Tel: 0917-3248233

Fax: 0917-3376021

Mobile: 13759795286

E-mail: info@inno-ti.com

E-mail: sales@inno-ti.com

|

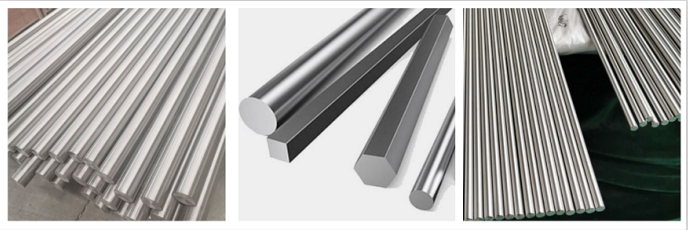

Titanium Bar:

Specification and Standard for Titanium Bar and Its Alloys:

|

|||

|

Products

|

Processing Standard

|

Grade

|

Size

|

|

Titanium Bar, Forging Bar

Round/Square, Rectangle/Hexagon

|

ASTM B348

AMS 4928

AMS 6921

ASTM F67

ASTM F136

etc.

|

Commercial Pure Ti:

(Grade 1-4)

Grade 5: Ti-6AI-4V

Grade 6: Ti-5AI-2.5Sn

Grade 7: Ti-0.2Pb

Grade 9: Ti-3AI-2.5V

Grade 12: Ti-0.3Mo-0.8Ni

Grade 23: Ti-6AI-4V ELI

Ti-6-2-4-2,

Ti-6-6-2

|

Common size for round bar :Φ(0.236”- 24”) x L

|

Commercially Pure Titanium

CP Titanium has a lower thermal expansion and shrinkage than stainless steel. It has been used in the medical field for many years. Examples of medical devices include: joint replacement parts, dental implants, pacemaker housings, and surgical instruments. CP Ti is environmentally friendly as it does not release toxic heavy metal ions by corrosion. It does not pit, and is free from crevice and stress corrosion. It is broken into four grades.

Grade 1

Titanium Grade 1 is the most malleable of the grades of Ti. It has the highest formability, superb corrosion resistance and high impact toughness. It is most commonly available in the form of sheets and plates. It is primarily used for applications where formability is necessary. These applications include: architecture, medical industry, marine industry, auto parts, airframe structures, and chemical processing.

Grade 2

Titanium Grade 2 is slightly stronger than Grade 1, but otherwise shares a lot of the same qualities. It is also corrosion resistant. Grade 2 is known for its weldability. Like all other titanium grades, it is also strong. It does not lose its strength when it is deformed, making it very ductile and formable. Grade 2 Ti is usually purchased in bars, tubing, pipes, sheets and plates. The types of applications Grade 2 is used for include: architecture, power generation, medical industry, airframe skin, chemical processing, marine industry and hydro-carbon processing.

Grade 3

Titanium Grade 3 is the least used of the grades. It is stronger than Grades 1 and 2, similar in ductility, a little less formable, but it has higher mechanicals than Grades 1 and 2. If your application requires mid-range strength but massive corrosion resistance, Grade 3 is what you will want to use. Grade 3 applications include: chemical processing, medical and marine industries, and aerospace structures.

Grade 4

Titanium Grade 4 is the strongest of the pure Ti Grades. It is known for its corrosion resistance, and good formability and weldability. Grade 4 is used for applications where high strength is required. These applications include: heat exchangers, surgical hardware, cryogenic vessels, and airframe components.

6Al 4V (Grade 5)

Titanium Grade 5, also known as 6AI-4V, is the most commonly used titanium alloy. It can be heat treated to increase its strength. Grade 5 is lightweight and strong. It is formable and highly resistant to corrosion. Its applications are used in aerospace, medical, marine, and chemical processing industries. It can be used to make items like aircraft turbines, sports equipment, marine application, engine components and high-performance automatic parts.

Grade 7 ( Ti-0.2Pb)

Titanium Grade 7 has superb weldability and fabricality. It is also the most corrosion resistant of all the titanium alloys. Grade 7 is used in chemical processes and production of equipment components.

6AL-4EV ELI (Grade 23)

Titanium Grade 23 is very ductile. It is used for medical and dental applications. It is lightweight, resistant to corrosion and tough. It can be used in biomedical components and intricate surgical procedures. Examples include: orthopedic cables, pins and screws, ligature clips, surgical staples, orthodontic appliances, cryogenic vessels, bone fixation devices, and springs.

3AL-2.5V (Grade 9)

Titanium Alloy 3AL-2.5V (Grade 9) falls between Grade 4 and Grade 5 when it comes to strength. Like the other grades, it has fantastic corrosion resistance. It is used in applications in the aerospace and industrial industries. Grade 9 can be used in higher temperatures than the first four Grades. It also has good cold rolling elements. It can be used for mild oxidizing media and has good weldability

|

Total: 1

Page: 1 / 1

First

←Previous

Next→

End

|

titanium plate

titanium plate